Introduction

A spun propeller is a serious aviation incident that can render an aircraft uncontrollable, leading to catastrophic engine failure and potentially fatal consequences. This phenomenon occurs when one or more blades of a propeller separate from the hub due to excessive centrifugal force, usually caused by mechanical failure or over-speeding. To ensure the safety of the skies, it is imperative for pilots and aircraft maintenance personnel to understand the causes of spun propellers and master the techniques for their repair.

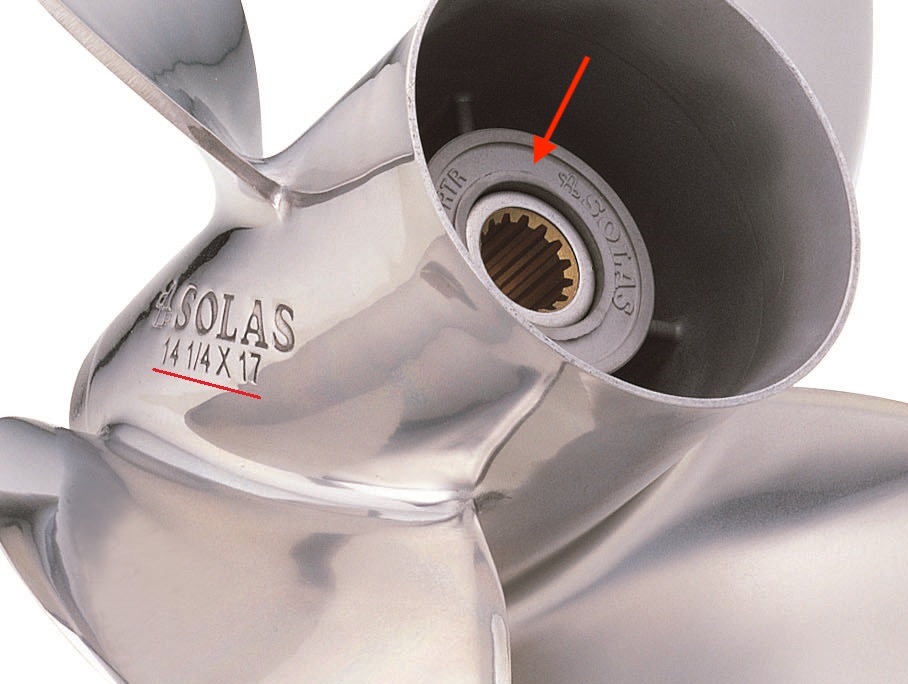

Image: boattest.com

Understanding Spun Propellers

A spun propeller is characterized by the complete separation of one or more blades from the propeller hub. This catastrophic event can occur during flight, typically due to excessive engine speed or a preexisting structural weakness in the propeller. When a blade spins off, it creates an unbalanced force on the remaining blades, causing severe vibration and impairing the aircraft’s controllability.

Causes of Spun Propellers

Spun propellers can result from a variety of factors, including:

- Over-speeding: Exceeding the maximum allowable revolutions per minute (RPM) for a propeller can put excessive stress on the blades, leading to structural failure.

- Mechanical Failure: Faulty or damaged components, such as bearings, gears, or bolts, can cause the propeller to spin out of control.

- Propeller Blade Damage: Cracks, nicks, or corrosion on the propeller blades can weaken them, making them more susceptible to spinning off.

- Improper Installation: Incorrectly installing the propeller or failing to properly tighten the mounting bolts can result in the propeller becoming detached during operation.

- Resonance: In some cases, the propeller’s natural frequency can resonate with the engine’s operating frequency, causing excessive vibration that can ultimately lead to a spun propeller.

Identifying a Spun Propeller

Recognizing the signs of a spun propeller is essential for quick and effective action. The following symptoms may indicate a spun propeller:

- Unbalanced Vibration: The aircraft experiences severe and unusual vibration, particularly at high power settings.

- Loss of Control: The aircraft becomes difficult to control, especially during maneuvers that require precise handling.

- Oil Leaks: Damaged engine components or the propeller hub may leak oil as a result of the spun propeller.

- Loud Noises: A spun propeller can create loud noises, such as banging or rattling, that are not typically heard during normal operation.

Image: www.reddit.com

Immediate Actions in Case of a Spun Propeller

If a spun propeller is suspected, immediate action is crucial to minimize its impact:

- Reduce Power: Throttle back the engine to idle power to reduce stress on the remaining blades.

- Maintain Control: Use the available controls to keep the aircraft stable and level.

- Communicate: Inform air traffic control of the situation and request an immediate landing.

- Emergency Landing: If possible, land the aircraft at the nearest suitable airport or suitable area.

Propeller Inspection and Repair

Once the aircraft has landed safely, a thorough inspection of the propeller is necessary to assess the damage and determine the appropriate repair procedure. This inspection should be conducted by a qualified aircraft mechanic or maintenance technician.

The repair of a spun propeller typically involves replacing the damaged blades and inspecting the propeller hub for any damage. If multiple blades have spun off, the propeller may need to be replaced entirely. Repairs must adhere to the manufacturer’s specifications and industry regulations to ensure the safe and reliable operation of the aircraft.

Preventing Spun Propellers

Preventing spun propellers is paramount to ensuring the safety of aircraft and their occupants. Regular maintenance and proper operating procedures are crucial for mitigating the risks:

- Regular Inspections: Conduct routine inspections of the propeller, including the blades, hub, and mounting assembly, to detect any potential defects or wear.

- Certified Maintenance: Ensure that all propeller maintenance, including inspections and repairs, are performed by certified professionals.

- Propeller Protection: Use propeller guards or covers to protect the blades from external damage during ground operations.

- Avoid Over-speeding: Always adhere to the specified RPM limits for the propeller during flight.

- Maintain Engine Health: Address any engine issues promptly to prevent excessive vibration or other conditions that could strain the propeller.

How To Fix A Spun Propeller

Conclusion

Spun propellers are alarming incidents that can compromise aircraft safety, but they can be prevented through meticulous maintenance, responsible operation, and a thorough understanding of their causes and consequences. By following industry