Introduction

An engine that runs smoothly relies on precisely synchronized components, ensuring harmony among pistons, valves, and various mechanical systems. When this synchronization falters, it can lead to engine malfunctions, diminished performance, and potentially costly repairs. This article delves into the complexities of engine synchronization, its underlying causes, and proven strategies for resolving these issues.

Image: eld.report

Understanding Engine Synchronization

Engine synchronization refers to the coordinated movement of engine components during their operation. This includes the timing of fuel injection, valve opening and closing, and ignition events. The precision of these actions ensures optimal combustion and efficient power generation. Synchronization is essential for maintaining proper engine speed, reducing emissions, and preventing premature wear and tear.

Common Causes of Engine Synchronization Malfunctions

- Cam and Crankshaft Timing Issues: Misaligned timing belts or chains can disrupt the timing of valve and piston movements.

- Fuel Injector Malfunctions: Irregular fuel delivery or clogged injectors can impact combustion timing.

- Ignition System Faults: Faulty spark plugs, ignition coils, or wiring can affect the timing of ignition events.

- Sensor Failures: Malfunctioning sensors, such as camshaft position sensors or crankshaft position sensors, can provide inaccurate data, leading to synchronization problems.

Diagnosis and Troubleshooting

Diagnosing engine synchronization malfunctions involves analyzing symptoms, such as rough idling, engine misfires, or power loss. Mechanics use specialized equipment, such as scan tools and oscilloscopes, to identify the root cause. Troubleshooting often includes checking timing belt or chain alignment, inspecting fuel injectors, and diagnosing ignition system components.

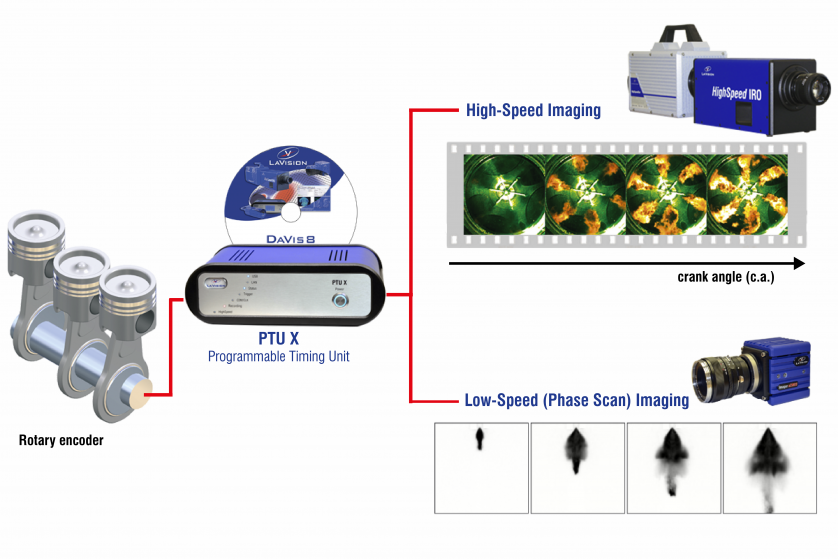

Image: www.lavision.de

Repairing Engine Synchronization Malfunctions

The repair process varies depending on the source of the malfunction. In some cases, a simple adjustment of timing components or replacement of faulty injectors may suffice. More complex issues, such as camshaft or crankshaft misalignment, may require engine disassembly and extensive repairs. It’s crucial to seek professional assistance from qualified mechanics who specialize in the specific type of engine.

Advanced Synchronization Techniques

Modern engine management systems employ sophisticated electronic controls to optimize synchronization. Variable valve timing and direct injection systems allow engines to adjust to varying operating conditions, maximizing efficiency and power output. Advanced synchronization techniques also include adaptive learning algorithms that continuously fine-tune engine performance based on driving patterns and environmental factors.

Benefits of Proper Engine Synchronization

- Improved Performance: Optimal synchronization ensures efficient power generation, resulting in better acceleration and responsiveness.

- Reduced Emissions: Precise timing minimizes unburnt fuel and optimizes combustion, leading to lower emissions.

- Enhanced Fuel Economy: Improved synchronization reduces wasted energy, resulting in better fuel efficiency.

- Increased Engine Life: Properly synchronized components reduce wear and tear on engine parts, extending their lifespan.

How To Fix Engine Synchronization Malfunction

Conclusion

Engine synchronization is a critical aspect of engine performance, directly impacting vehicle efficiency and reliability. Understanding the principles of synchronization, common causes of malfunctions, and repair strategies empowers drivers and mechanics to diagnose and resolve these issues effectively. It’s essential to maintain proper synchronization to ensure optimal engine performance, minimize emissions, and extend the longevity of the vehicle.